Pre-Engineered Buildings in Pakistan – Design, Fabrication, & Erection by KEFAB

A Pre-Engineered Building (PEB) is a metal structure manufactured in a factory and assembled on site. In Pakistan, pre-engineered buildings are commonly used for warehouses, factories, logistics hubs, and cold storage facilities because they are quick to construct, long-lasting, and cost-effective.

At KEFAB, we are your reliable source for PEB services in Pakistan, providing complete services including design by PEC-registered engineers, 3D modeling, BOQ preparation, in-house fabrication, transportation, and HSE-compliant erection. With 20+ years of experience and 80+ completed projects, KEFAB ensures every PEB structure meets AISC, MBMA, and AWS standards for quality, safety, and compliance.

Proven Track Record in Pre-Engineered Buildings Across Pakistan

KEFAB is one of the top pre-engineered building manufacturers in Pakistan, offering complete PEB services backed by 20+ years of experience. From clear-span warehouses and cold storage to custom office and factory buildings, we deliver structures that are strong, accurate, and cost-effective. Every project is engineered using the latest tools—like 3D modeling, BOQ transparency, and QA-monitored fabrication—to meet client needs. With 80+ projects completed nationwide, we continue to lead the way in delivering durable PEB structures in Pakistan that perform reliably.

What Are Pre-Engineered Buildings (PEBs) in Pakistan?

Pre-engineered buildings (PEBs) are factory-produced steel structures that are transported to the site for fast-track installation. Instead of relying on traditional brick-and-mortar methods, PEBs use modular steel frames and prefabricated panels that make them lighter, stronger, and more economical. In Pakistan, they are widely adopted for industrial warehouses, logistics hubs, cold storage facilities, and large-span sheds, where speed of construction and structural safety are critical. Backed by PEC-registered engineers and international quality standards (AISC/MBMA/AWS), KEFAB ensures each PEB project combines durability, compliance, and cost efficiency.

Key Components of Pre-Engineered Buildings (PEB)

A Pre-Engineered Building (PEB) is a complex structure made up of several key components that work together to provide a strong, safe, and efficient building. These components are carefully designed and manufactured to ensure that they meet the required standards of quality, durability, and performance.

The main components of a PEB can be broadly categorized into structural, roofing, walling, and finishing components. Each of these components plays a critical role in ensuring that the building is safe, secure, and functional. We use quality materials in every PEB component, from the main frames to the roofing and walling systems, to make our buildings stronger and more durable, differentiating us from other PEB builders in Pakistan. Some of the key components of a PEB include:

Main Frames Or Vertical Columns

The main frames are the backbone of a pre-engineered building (PEB). They are made up of strong steel columns and rafters that are shaped to fit together perfectly. These frames are made in a factory using special machines and are then transported to the building site.

End Wall Framing

The end wall framing is a structural element of the PEB. It is made up of columns and rafters that are connected together to form a solid wall. This framing is designed to support the weight of the building and keep it stable.

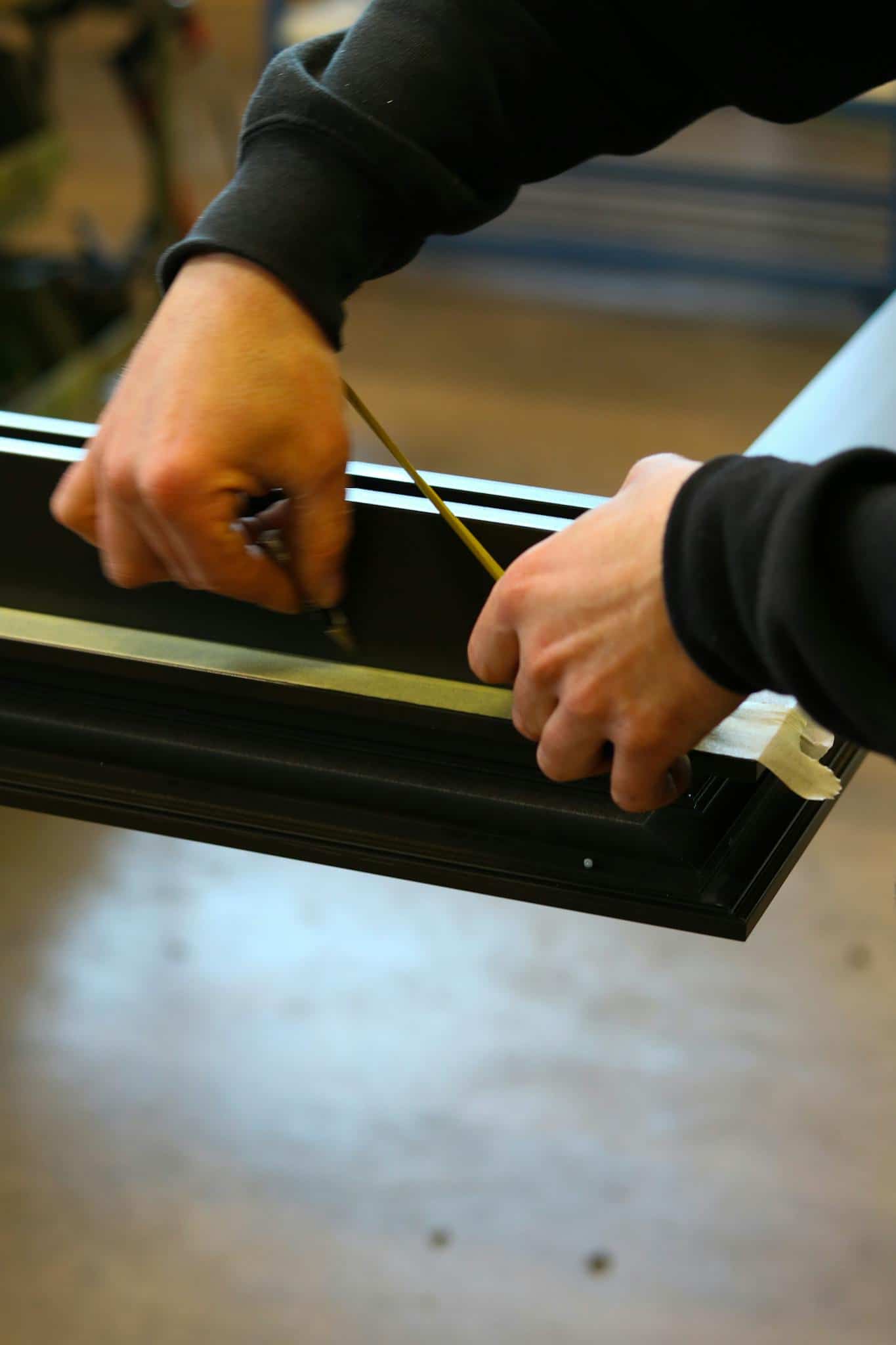

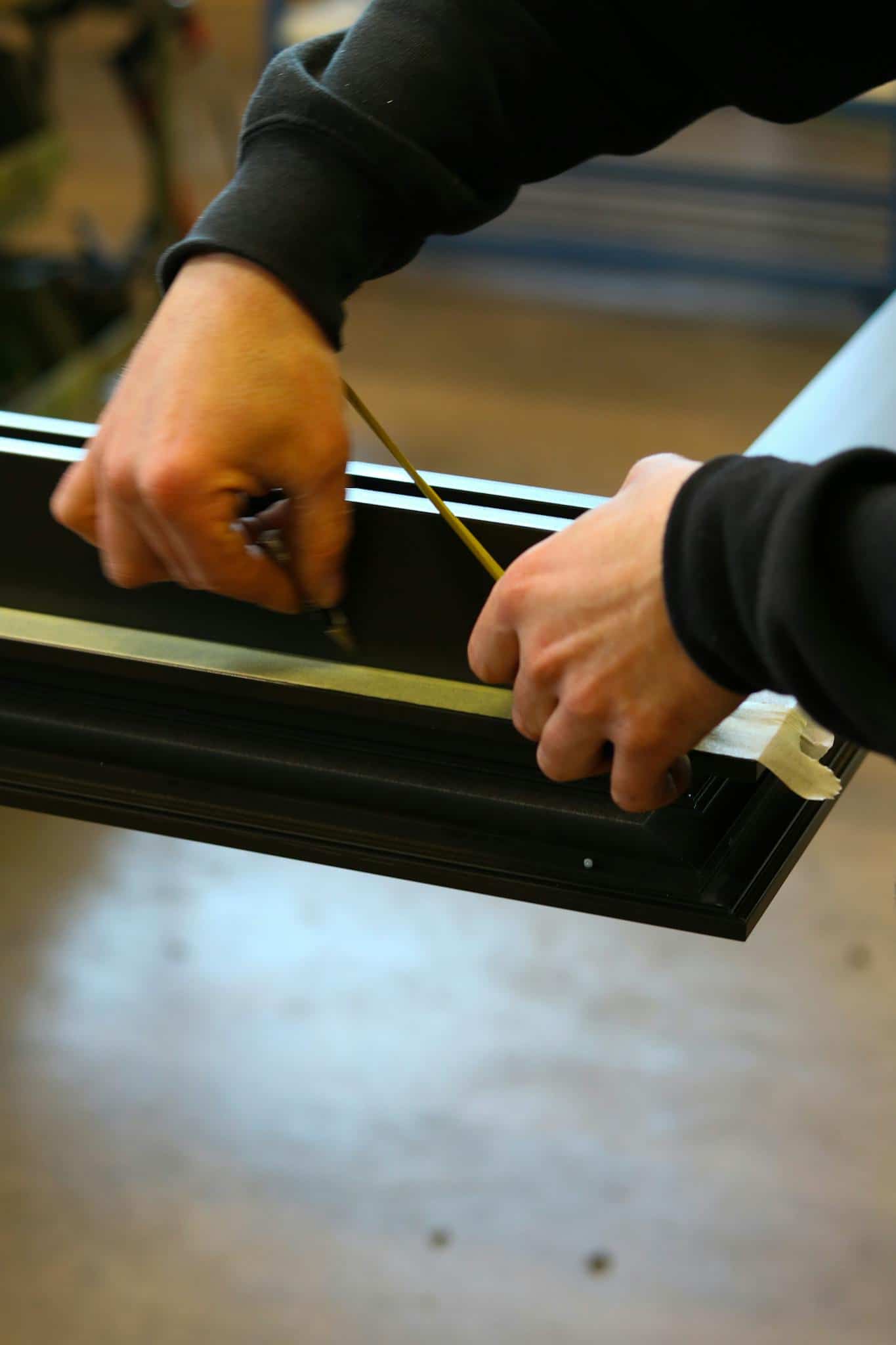

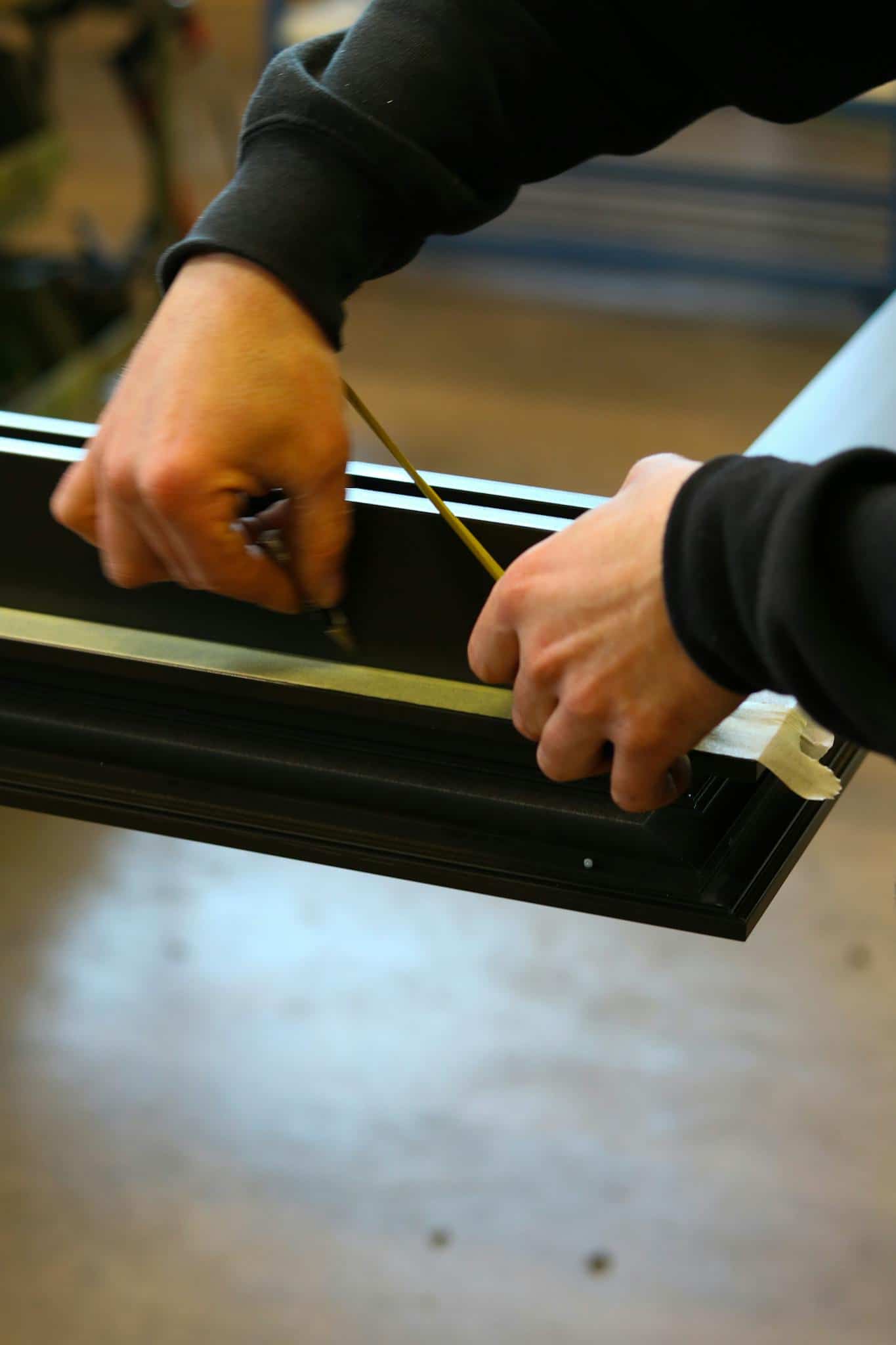

Purlins, Girts, and Eave Struts

Purlins, girts, and eave struts are secondary members of the PEB that provide support to the roof and walls. Purlins are horizontal beams that support the roof, while girts are vertical beams that support the walls. Eave struts are diagonal beams that connect the roof to the walls. These parts are made from steel coils that are shaped and welded together.

Crane System

A crane system is a special feature of some pre-engineered buildings. It is a network of beams and rails that allow cranes to move heavy loads around the building. This system is designed to improve safety and efficiency in the workplace.

Sheeting and Insulation

The sheeting and insulation of a PEB are designed to keep the building warm in the winter and cool in the summer. The sheeting is made from galvanized steel that is coated with a special layer to prevent rust. The insulation is made from foam boards or fiberglass batts that are placed between the sheeting and the building.

Mezzanine System

A mezzanine system is a raised platform that is built inside a PEB. It is made from steel beams and decking, and is designed to provide extra storage or working space. Mezzanine systems are often used in warehouses and factories.

Paints and Finishes

The paints and finishes used on a PEB are designed to protect the steel from rust and corrosion. The steel is coated with a layer of paint or other protective material that helps to extend its lifespan.

Doors and Windows

Doors and windows are important features of any building, including PEBs. They are designed to provide natural light and ventilation, as well as secure entry and exit points. Doors and windows can be made from a variety of materials, including steel, aluminum, and glass.

Roofing

The roofing of a PEB is designed to keep the building dry and secure. It is made from galvanized steel sheeting that is coated with a special layer to prevent rust. The roofing is also designed to allow snow and water to run off easily.

Foundation

The foundation of a PEB is the base of the building that sits on the ground. It is made from concrete or other materials, and is designed to provide a solid base for the building. The foundation is also designed to transfer the weight of the building to the ground.

Anchoring System

The anchoring system of a PEB is designed to hold the building securely to the foundation. It is made from steel anchors and bolts that are embedded in the concrete foundation. The anchoring system helps to prevent the building from shifting or toppling over.

Bracing System

The bracing system of a PEB is designed to provide additional support and stability to the building. It is made from steel beams and cables that are connected to the main frames and foundation. The bracing system helps to prevent the building from collapsing or shifting in strong winds or earthquakes.

Types of Pre-Engineered Buildings (PEBs)

Pre-engineered buildings (PEBs) have changed the construction industry with their smart design, efficiency, and flexibility. These buildings are made up of standard parts that fit together easily, allowing for fast construction and customization to suit different needs and uses. With various types to choose from, including Clear Span, Single Slope, Multi-Span, and more, Pre-engineered buildings offer a range of options to suit diverse architectural and functional requirements. We offer different types of Pre-Engineered Buildings to suit your specific needs:

These pre-engineered buildings have a wide, open space inside, with no columns or obstructions to hinder movement or placement of equipment. Clear span buildings are perfect for large projects like:

1. Warehouses

2. Factories

3. Airports

4. Sports arenas

5. Exhibition halls

They offer maximum flexibility in interior layout and usage, and are ideal for applications requiring large open areas.

These buildings have a roof that slopes in one direction, providing efficient rainwater drainage and runoff. Single slope buildings are great for projects that need a simple and cost-effective solution, such as:

1. Warehouses

2. Distribution centers

3. Manufacturing facilities

4. Agricultural buildings

They are easy to construct and maintain, and offer a cost-effective solution for projects with sloped roof requirements.

These buildings have multiple sections with different spans, offering flexibility in design and functionality. Multi-span buildings are perfect for projects that require:

1. Large open areas

2. Multiple levels or mezzanines

3. Complex architectural designs

We offer three types of multi-span buildings:

MS1: Equal spans with uniform spacing between columns.

MS2: Unequal spans with varying spacing between columns.

MS3: Clear spans in some areas and multi-span sections in others.

These buildings have multiple gable ends, providing a unique and attractive design. Multi-gable buildings are perfect for projects that require:

1. Architectural aesthetics

2. Complex roof designs

3. Multiple levels or mezzanines

They offer enhanced structural stability and efficient rainwater drainage, making them a popular choice for:

1. Commercial offices

2. Retail stores

3. Restaurants

4. Hotels

These buildings are extensions attached to existing structures, providing additional space and flexibility. Lean-to buildings are perfect for projects that require:

1. Additional storage space

2. Workshop areas

3. Office spaces

4. Residential areas

They are easy to construct and maintain, and offer a cost-effective solution for projects that require additional space.

These pre-engineered buildings combine different construction methods to create a unique solution. Hybrid structures are perfect for projects that require:

1. Complex architectural designs

2. Multiple levels or mezzanines

3. Unique structural requirements

We offer customized hybrid structures that combine the benefits of different construction methods, providing a tailored solution for your specific project needs.

Key Characteristics of Pre-Engineered Buildings:

Here are some key characteristics of Pre-engineered Buildings:

1. Designed and manufactured in a factory

PEBs are created in a controlled environment, ensuring quality and precision.

2. PEB’s are created in a controlled environment, ensuring quality and precision.

Prefabricated members supporting the walls, roofs, floors, and other elements are pre-assembled in the factory in order to cross-check the levels & dimensions before delivering the material to site.

3. Quick assembly on-site

PEB’s can be rapidly installed on-site, reducing construction time.

4. Customizable

PEB’s can be tailored to meet specific requirements, such as size, shape, and functionality.

5. Cost-effective

PEB’s can be more affordable than traditional construction methods.

6. Durable and low maintenance

PEB’s are built to last, with minimal maintenance required.

Testimonials

Read what our customers have to say about their experience with Kefab.

Reliable Pre-Engineered Buildings Solution for Pakistan’s Industries

At KEFAB, we provide tailor-made Pre-Engineered Building (PEB) solutions designed to meet the unique demands of Pakistan’s industrial and commercial sectors. By combining advanced engineering, durable steel frames, and prefabricated panels, we deliver structures that are efficient, cost-effective, and built to last.

Our pre-engineered buildings expertise covers a wide range of applications, including:

Construction and

Real Estate

We serve construction companies, developers, and contractors, providing prefabricated steel buildings, structural steel fabrication, and steel construction services.

Industrial and Manufacturing

Our PEB services cater to industrial clients, including metal building construction, steel framing, and structural steel fabrication for factories, warehouses, and production facilities.

Commercial and Retail

We provide PEB services for commercial and retail clients, including prefabricated steel buildings, steel structure design, and installation for offices, shopping centers, and restaurants.

Agricultural and Rural

Our steel solutions serve agricultural clients, including metal building construction, steel framing, and structural steel fabrication for farms, barns, and rural buildings.

Government and Infrastructure

We cater to government agencies and infrastructure projects, providing steel construction & PEB services, including prefabricated steel buildings, steel structure design, and installation for public buildings, roads, and bridges.

Healthcare and Pharma

We serve the healthcare and pharmaceutical industries, providing steel construction solutions for hospitals, clinics, medical facilities, laboratories, research facilities, and production plants, including prefabricated steel buildings, steel structure design, and installation services.

Petroleum

Providing resilient steel structures for refineries and storage facilities, we support the petroleum industry’s critical infrastructure needs with prefabricated steel buildings and structural steel fabrication.

Textile

From manufacturing facilities to warehouses and distribution centers, our customized steel buildings and PEB design services cater to the textile industry’s complex requirements.

Wood Industry

Durable steel framing and construction services for woodworking facilities, sawmills, and timber processing plants are our focus, meeting the demanding needs of the wood industry with expertise and quality.

Food Industry

Ensuring food safety and quality, our hygienic steel construction solutions and efficient storage systems serve food processing plants, warehouses, and distribution centers with reliability and precision.

Automobile

Supporting the automotive industry’s evolving needs, we offer customized steel buildings, specialized steel fabrication, and steel construction services for manufacturing facilities, showrooms, and service centers.

We take pride in designing and delivering Pre-Engineered Buildings (PEBs) that are customized for each industry’s unique requirements, ensuring superior quality, precise engineering, and fast-track project delivery.

Our Completed Projects

Our Pre-Engineered Building (PEB) Services Execution Process

Request a Quote

Get started by requesting a quote for your pre-engineered buildings project. Our experts will assess your requirements and provide a personalized quote, outlining the scope, timeline, and cost of your custom-built structure, including competitive pre-engineered metal buildings prices.

Hire Us

Once you approve our quote, we’ll send over a formal agreement outlining the terms and conditions of our partnership. This marks the beginning of our collaboration to bring your PEB vision to life.

Meet Your Requirements

Our team will work closely with you to understand your specific needs, goals, and timelines. We’ll conduct site assessments, discuss design options, and ensure our PEB solution meets local building codes and regulations, delivering a customized structure that meets your requirements for quality, durability, and functionality.

Why Choose Us as Your Trusted Pre-Engineered Building Manufacturer for Your PEB Structure in Pakistan?

At KEFAB, we understand the importance of reliable and efficient pre-engineered metal building solutions. That’s why we offer top-notch PEB structures designed to meet your unique needs. Here’s what sets us apart:

Our team of experienced professionals has extensive knowledge in designing and building customized PEB services.

We ensure top-notch quality in our pre-engineered buildings, using high-grade materials and advanced manufacturing techniques.

Our PEB services are customized to fit your specific requirements, whether it’s for industrial, commercial, or residential projects.

Our professional team provides exceptional customer support, ensuring a smooth experience from design to installation.

We optimize your investment with cost-efficient solutions that balance quality, functionality, and affordability, ensuring maximum value for your budget.

We pride ourselves on meeting deadlines, ensuring your PEB structure is delivered and installed on schedule, so you can start using it sooner

Clients

Where We Serve?

– Karachi

– Lahore

– Islamabad

– Rawalpindi

– Faisalabad

– Multan

– Hyderabad

– Peshawar – Quetta

– Gujranwala

– Sialkot

– Bahawalpur

– Sukkur

– Larkana

– Rahim Yar Khan

– Dera Ghazi Khan

PEB Frequently Asked Questions:

Let’s Get Started to Bring Your PEB Vision to Life!

Get in touch with KEFAB today to discuss your Pre-Engineered Building (PEB) requirements. Our team will provide clear guidance and professional support from the first consultation to final delivery.

Phone Number

+923339971876 | +923343722355

Hours of Operations

Monday to Saturday

9 AM–6 PM

Sunday

Closed